TECH TIP – Smoothing Out Your Ride

A lot of HOG riders sometimes think that the ”V” in V-twin stands for vibration. This idea comes from the unique mechanical activity that takes place down in our bike’s drivetrain. First you have a couple of pistons and connecting rods moving up and down inside two cylinders. They are not operating in a completely balanced non-vibrating environment. This unbalanced motive power is sent to the transmission through a primary drive that uses a spring tensioned motor sprocket and chain drive assembly running back to the transmission. The bike’s final drive runs a reinforced cog belt back to the rear wheel. On 2009-up models, the wheel’s drive sprocket has a rubber isolator that fits in a cavity between the sprocket’s hub and the wheel’s hub.

Harley calls this system a compensator sprocket, which allows the hub to absorb some of the powertrain shock when starting off from a stop and when the rider lets off the throttle. If you ride hard, this isolator’s flexible material can put a double drivetrain bump into your rear wheel during hard acceleration.

The boys at Alloy Art have developed a replacement rear wheel isolator that eliminates this double bump. Their isolator is made out of a firmer injection molded polyurethane material. We installed one in a 2013 Street Glide and the bike’s throttle response and drivetrain tractability had a much more solid feel; if we hadn’t ridden the bike before and after the isolator was installed, we wouldn’t believe that one part could make such a big difference. The Alloy Art super Cush-Drive Isolator retails for $39, which could just be the best forty bucks you’ve ever spent on your bagger.

– John Sullivan

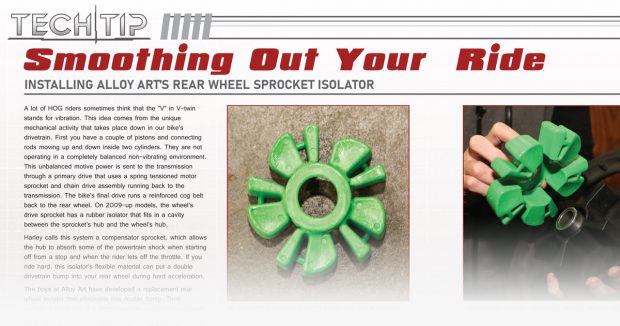

THE ALLOY ART CUSH-DRIVE ISOLATOR IS MADE OUT OF A MUCH MORE RESILIENT MATERIAL THAN THE FACTORY PART.

TO AVOID ANY ASSEMBLY HEADACHES, WE FIRST TEST-FIT THE ISOLATOR ONTO THE BACK OF THE WHEEL’S DRIVE SPROCKET.

THE ISOLATOR’S FIT TO THE SPROCKET IS IN SUCH A WAY THAT ITS THICKER SEPARATORS ARE USED IN THE DRIVE ROTATION.

WE FIT THE ISOLATOR INTO THE REAR WHEEL’S LEFT SIDE HUB. IT IS A TIGHT FIT AND DESIGNED SO THAT IT CAN ONLY BE INSTALLED ONE WAY.

THE ISOLATOR IS FIRST SET INTO THE WHEEL’S HUB, AND THEN THE DRIVE SPROCKET IS SET OVER IT.