Tech Tip – Inside Harley’s Milwaukee-Eight Motor

Checking Out Their 4-Valve Heads

With the 2017 introduction of their Milwaukee-Eight motor, H-D finally stepped into the twenty-first century! The major reason for saying this is, that’s when they fitted their big-twin powered bikes with a completely new motor, which they named the Milwaukee-Eight. For the regular Softail and touring line-up, it displaces 107-cubic inches and in their CVO and performance bikes, it has 114-inches of displacement. Along with the larger displacement, it had several new features: one of which is that it has four valves and two spark plugs per cylinder.

Along with these power improvements, there were several mechanical changes designed to decrease the amount of excess heat that the motors generate. This was accomplished three ways: by increasing the cooling fins on the cylinder heads, by lowering the motor’s idling speed and by adding a secondary cooling system on all of the motors’ cylinder heads. The standard motors now feature oil-cooled exhaust ports while the motors in the heavier bikes, the trikes and the CVO models, use a liquid cooling system that is similar to the one H-D has equipped these bikes with for the past several years.

Harley’s engineers also improved the motor’s low-end torque. They were able to do this because the four-valve layout in the cylinder heads allowed them to shorten the valve timing on the intake valves. Also, in the four-valve layout, each valve has a smaller port, which increases the intake charge speed inside of the ports. This means that the motor doesn’t need the intake valves to open before the piston reaches top dead center, which increases the motor’s lower RPM efficiency.

All of these developments were big improvements over H-D’s previous V-twins. So, before you dump a fist full of green-backs into a Twin-Cam motor’s innards, visit your local H-D dealer to take a test ride on a Milwaukee-Eight powered bike. Which we think you will be impressed with.

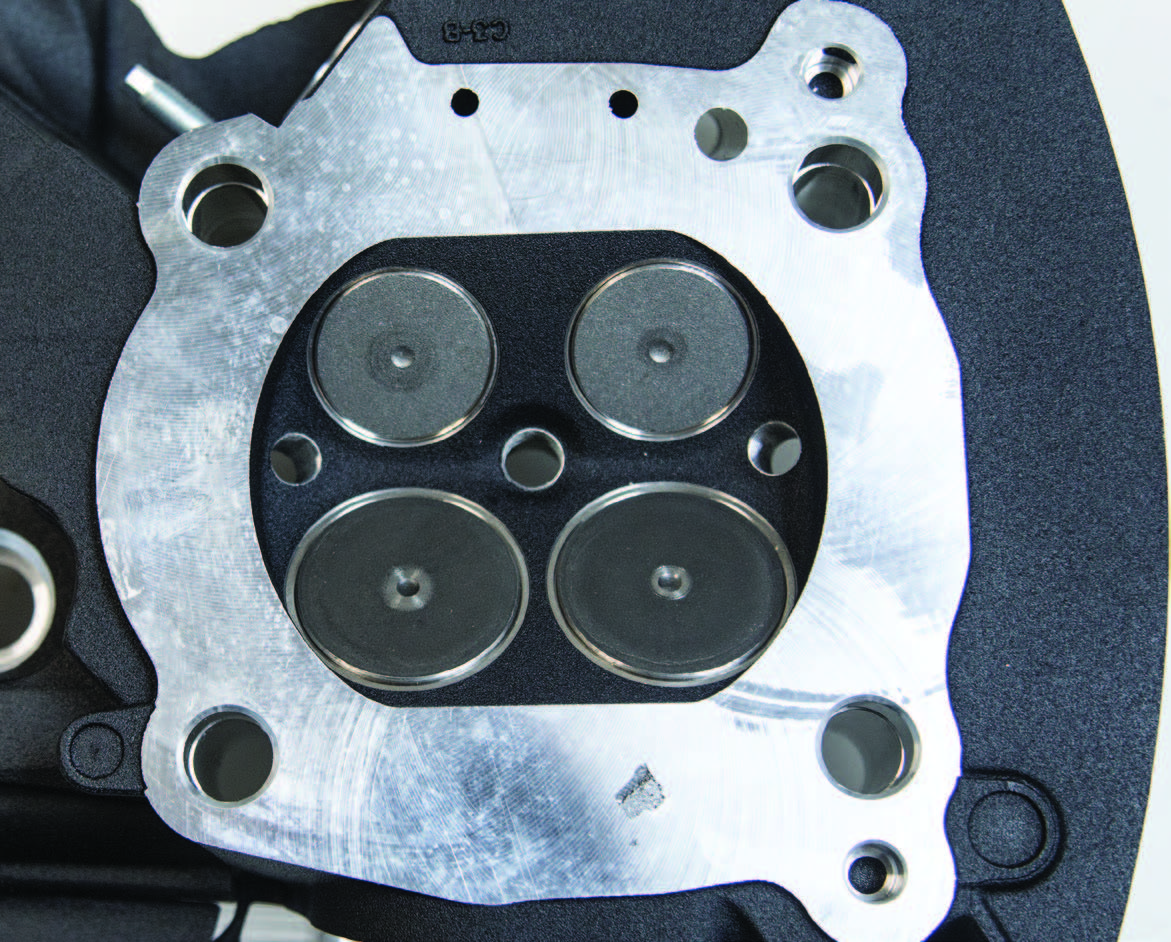

THE MILWAUKEE-EIGHT’S COMBUSTION CHAMBER IS A 4-VALVE DESIGN. THIS IS A MAJOR IMPROVEMENT OVER THE TWIN-CAM’S 2-VALVE SYSTEM. HAVING TWO SMALLER INTAKE VALVES IN EACH COMBUSTION CHAMBER IMPROVES THE MOTOR’S LOW RPM PORT VELOCITY; YET THEIR OVERALL SURFACE AREA IS GREATER THAN THE TWIN-CAM’S SINGLE VALVES, WHICH IMPROVES THE MOTOR’S CYLINDER FILL RATE.

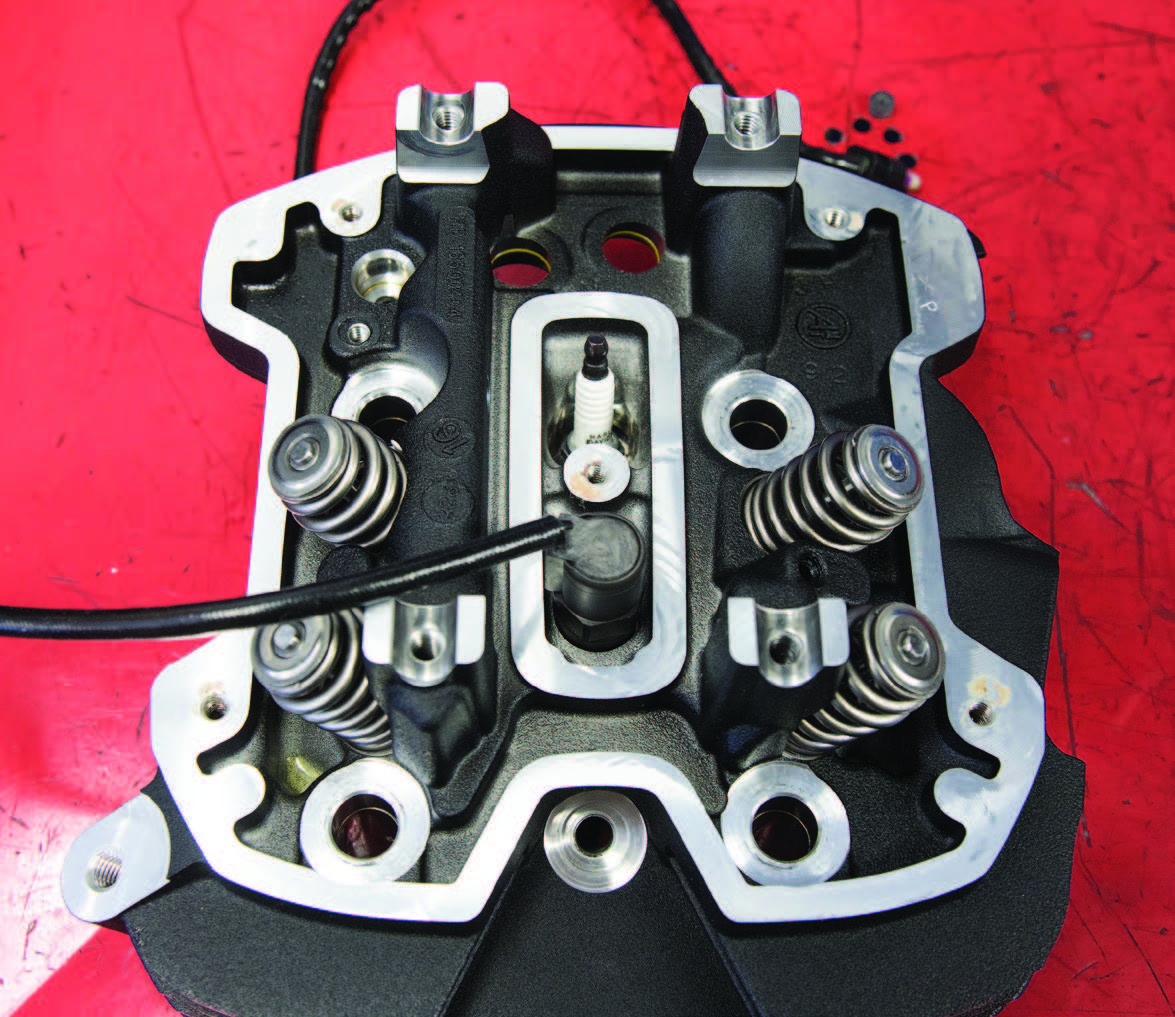

ALONG WITH THE SMALLER VALVE SPRINGS, THE TOP OF THE NEW CYLINDER HEADS HAS FOUR RAISED MOUNTING STANDS THAT THE ROCKER ARMS ARE BOLTED TO.

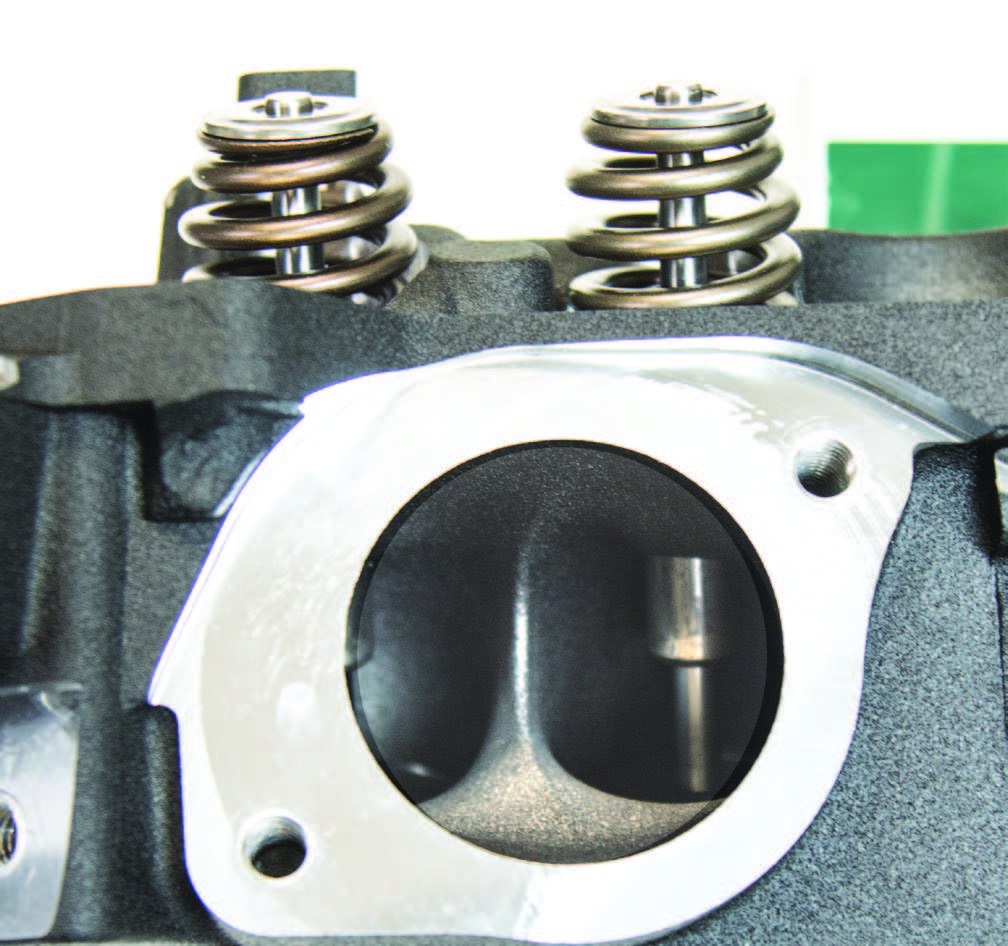

THE NEW CYLINDER HEADS’ INTAKE PORTS USE SEPARATE PASSAGES FROM EACH VALVES’ HEAD TO ABOUT HALFWAY BACK TO THE PORTS’ MOUNTING SURFACE, WHERE THEY MERGE INTO A SINGLE LARGE PORT. THE EXHAUST PORTS HAVE THIS SAME DESIGN.

THE VALVE SPRINGS IN THE MILWAUKEE-EIGHT MOTORS HAVE ABOUT 1/3 THE STATIC PRESSURE OF THOSE USED IN THE TWIN-CAM MOTORS. THIS WILL GREATLY REDUCE THE WEAR TO THE CAMSHAFT LOBES.

THE CYLINDER HEADS’ SECOND SPARK PLUG IS LOCATED IN A POCKET IN THE CENTER OF THE CASTING, WHICH IS NOT EASILY ACCESSIBLE. CHANGING THIS SPARK PLUG REQUIRES RAISING UP THE GAS TANK AND USING A SPECIAL TOOL TO PULL THE PLUG WIRE OFF OF THE SPARK PLUG. THE DEVICE NEXT TO THE SPARK PLUG IS THE COMPRESSION RELEASE.

TO FURTHER REDUCE THE MOTOR’S OPERATING TEMPERATURE, THE STANDARD MILWAUKEE-EIGHT MOTOR HAS OIL-COOLED EXHAUST PORTS.

Copy & Images: John Sullivan