Inside Harley’s Milwaukee-8 Big-Twin – Finally, A Better Oiling System

If Harley’s Twin-Cam powered bikes had an Achilles heel, it was the motor’s oiling system. During the twenty some years that it was produced, a lot of people looked into and worked on this problem. Most of the attention was directed at the oil pump, its pressure relief valve and the mounting plate. Harley’s Screamin’ Eagle performance division, and more than a couple of aftermarket companies, developed hi-volume oil pumps and hi-flow cam plates that featured adjustable oil pressure regulator valves, other companies came up with regulator valve modification kits, some of which worked, while others didn’t.

In designing the Milwaukee-8 motor, Harley took a very long look at the Twin-Cam’s oiling system and came up with three changes to improve the new motors’ oil system. The first change was moving the oil pressure regulating valve to the oil pump housing. The second change involves the pressure regulator piston; it now has a step, instead of a taper on its closed end. The outer edge of the step is of a larger diameter than the hole in the oil pump’s bypass port, which makes a much more secure closure of the bypass port. The third change is in the actual oil pump itself; like the oil pump used in Twin-Cam motors, the Milwaukee-8’s oil pump is a double gyrotor system: a pressure pump and a scavenge pump. But the new oil pump is fitted with much larger diameter gyrotor assemblies, which increases the pumps’ volume. The scavenge pump’s gyrotor is also about 50% thicker than the pressure gyrotor. This increases the volume of oil that can be removed from the crankcase.

So, if you want a good reason to make the switch to a Milwaukee-8 powered bike, we just gave you three.

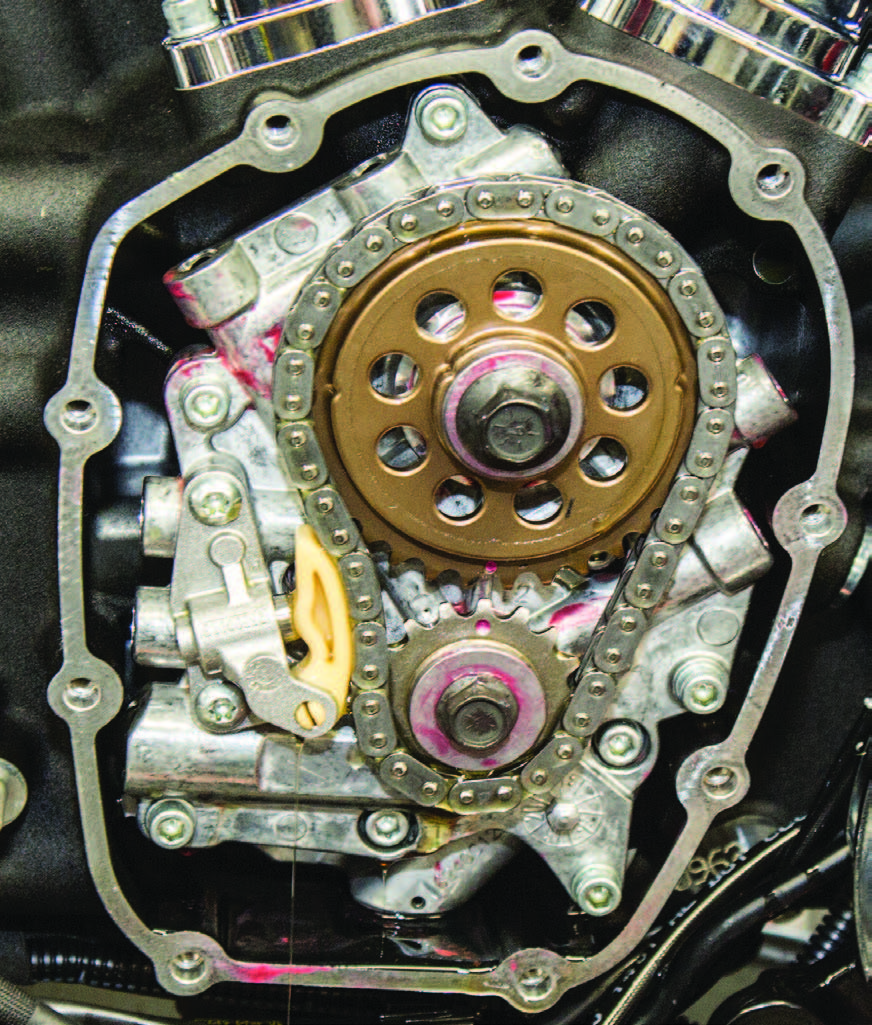

#1. The Milwaukee-8 motor’s oiling system sits behind it’s cam cover. The layout of the parts inside has a similar appearance to the Twin-Cam motor. The cam drive chain comes off as a unit with sprockets. Note the red timing marks on the sprockets, they must be aligned when installing the chain.

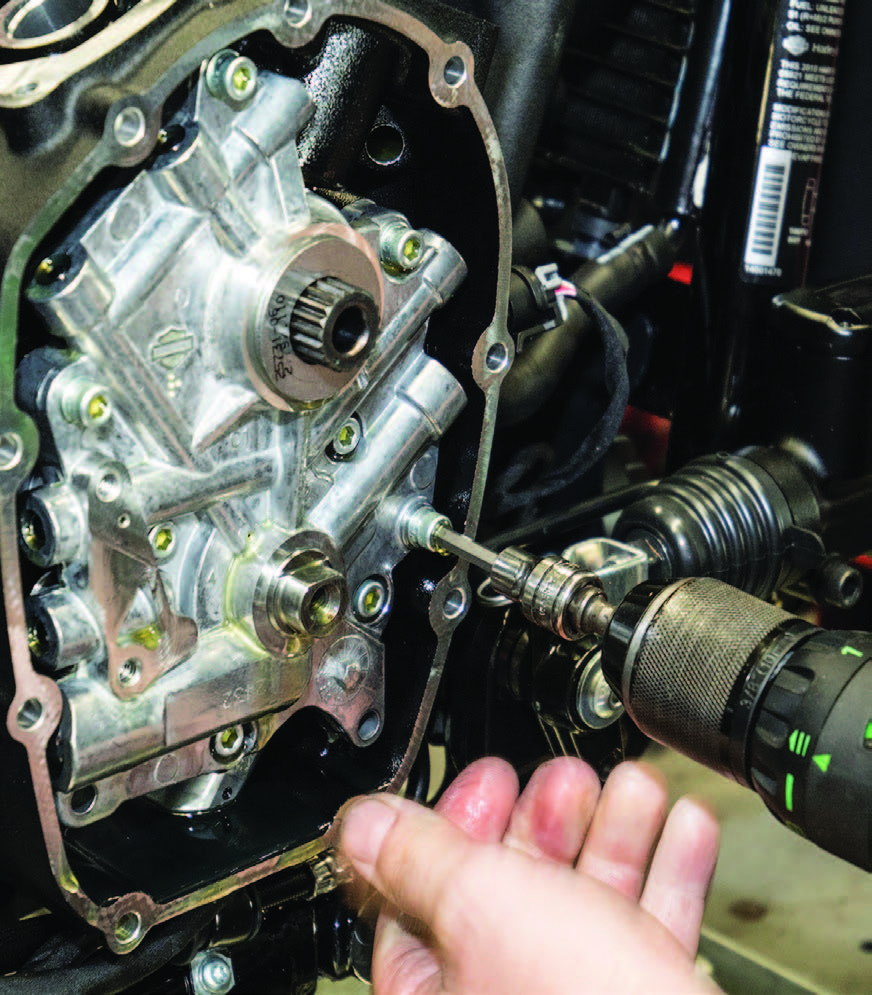

#2. The cam plate is secured with six Allen head bolts and the oil pump is attached to the cam plate with four Allen head bolts. This cam plate is pressure die-cast. It features integral bearings for the crankshaft and camshaft. To pull the cam plate, you must remove all ten of these bolts. The oil pumps will stay mounted on the right end of the crankshaft.

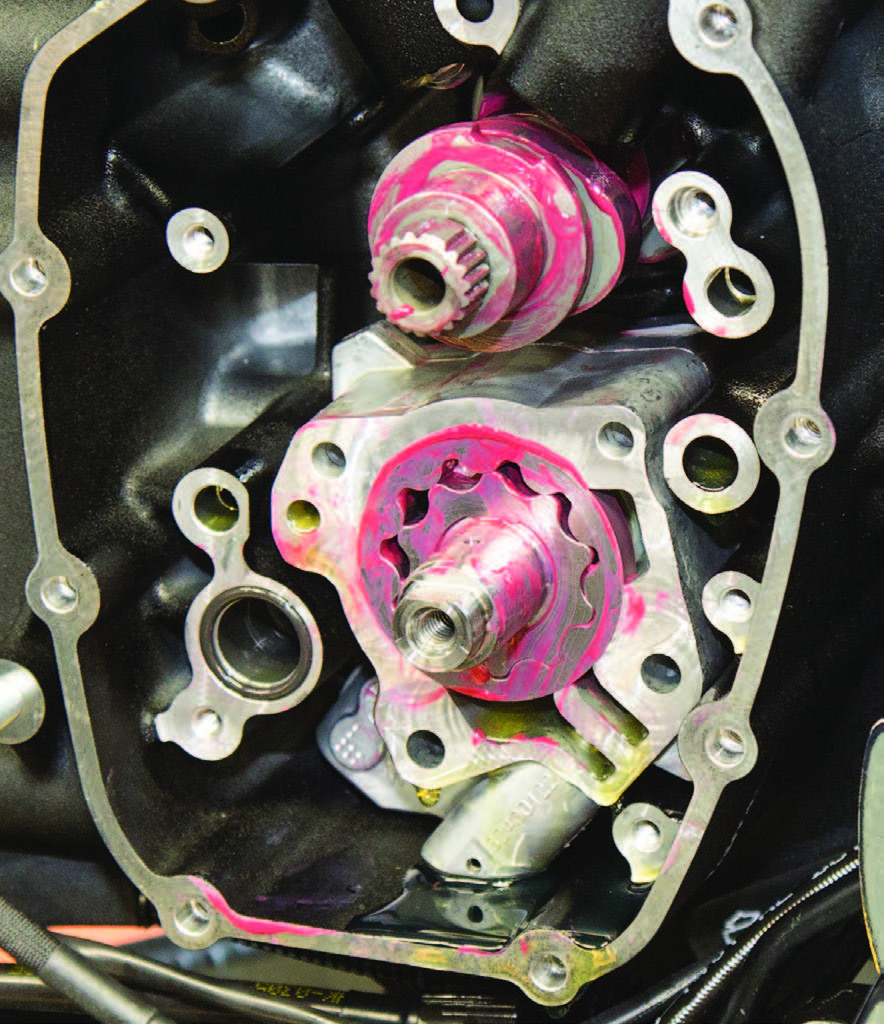

#3. This exposes the inner cam chest, the camshaft and the oil pumps. So here’s the big difference: the new motors use a single camshaft, which, is now driven directly from the crankshaft by a hydraulically tensioned chain.

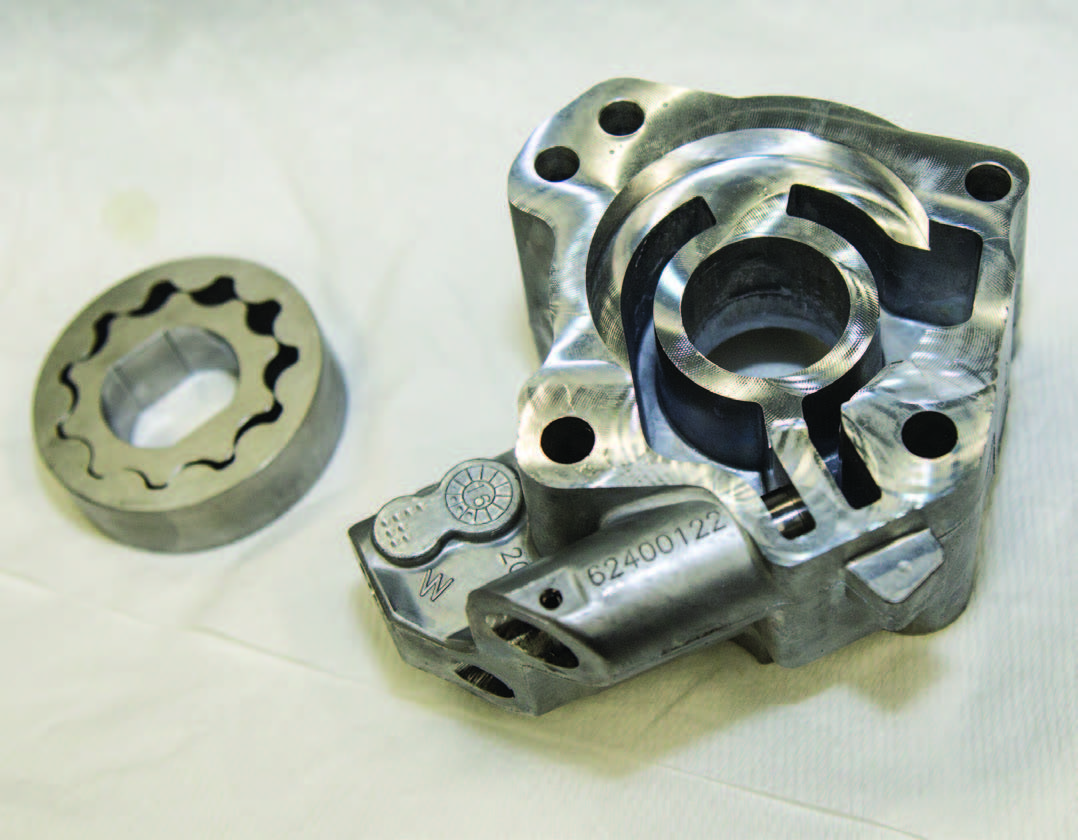

#4. The Milwaukee-8’s coiling system consists of a pair of gyrotor oil pumps, the pump housing, its back plate and a pressure relief valve. The pressure side of the oil pump (shown) uses a ten-lobe gyrotor pump that fits inside of the oil pump housing.

#5. The pressure regulator piston seals against a port on the inside of the oil pump housing. The oil pressure regulator valve consists of a steel piston, which has a step on its head, a compression spring and a split pin that holds them inside of the cam plate.

#6. This is a comparison of the pressure side gyrotor assemblies of the Twin-Cam motor, left, and the Milwaukee-8 motor, right. The Milwaukee-8’s larger gyrotor assembly should about double its oil volume to the motor’s internal parts.

– John Sullivan

Sources

Harley-Davidson Motor Company

Harley-davidson.com

If you have a Tech Tip you would like to see, let us know at editor@borntoride.com